The Concrete Sustainability Hub, CSHub, is a research center established at the Massachusetts Institute of Technology in collaboration with the Portland Cement Association and the Ready Mixed Concrete Research and Education Foundation. The dedicated team of interdisciplinary researchers from several MIT departments work on concrete and infrastructure science, engineering, and economics since 2009.

The MIT CSHub brings together leaders from academia, industry, and government, with the mission of accelerating emerging breakthroughs in concrete science and transferring the best available data into engineering practices. It is developing breakthroughs using a holistic approach that will achieve durable and sustainable homes, buildings, and infrastructure in ever more demanding environments.

According to initial results, the CSHub models are as accurate as or better than existing industry models.

MIT considered all impacts over the life of the pavement, not just initial manufacturing and construction.

Pavement Roughness and Fuel Consumption

Life-Cycle Assessment of Pavements

Life Cycle Cost Analysis or LCCA is an economic method used to assess the total cost throughout the life of a construction project. In the case of a road or highway, it includes not just the cost of initial construction, but the future cost of maintenance and rehabilitation required during the useful life of the project.

Accounting for Inflation in Life Cycle Cost Analysis

Buildings account for about 40% of U.S. energy consumption each year, more than either transportation or industrial sources.

MIT researchers conducted Life Cycle Analysis for single-family housing, multifamily housing, and commercial structures.

The studies considered all phases of a building’s life cycle: Producing building materials; Use of the building; Demolition and recycling at the end of its life.

Assessing the Full Impact of Buildings

Building Life Cycle Cost Analysis

For more information on all findings, please go to the CS Hub website.

As part of their “Tale of Two Homes” video series, PCA partner Federal Alliance for Safe Homes (FLASH) highlighted the use of concrete homes as a safe, resilient solution for disaster mitigation in a campaign timed for the one-year anniversary of Super Storm Sandy.

Also, as part of their disaster safety awareness campaign FLASH rolled out a video series on YouTube that tells the story of Seth Sochacki and his family, who survived Super Storm Sandy in an ICF home he built for his mother-in-law. The video tells how the family took refuge in the concrete house and watched as next door, their own wood frame home was washed away in the surge.

The video is targeted at homeowners and media with special attention to the New Jersey and New York markets. With the video, FLASH aims to establish and expand awareness of the disaster-resilience, durability, strength and sustainable benefits associated with building with concrete. In addition to the “Tale” piece, FLASH’s StrongHomes YouTube channel features videos of several PCA staff members discussing the benefits of concrete homes.

Please go to the PCA’s BuildingStronger splash page on the Think Harder site, to see the video and other resources.

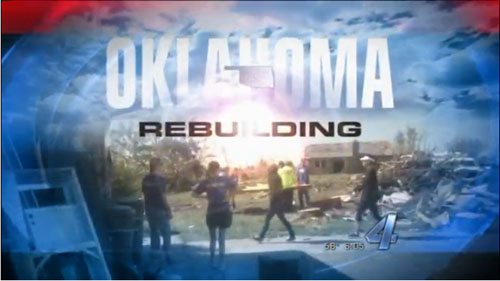

After losing all their possessions in the tornadoes that struck Oklahoma in May 2013, a Moore, OK, couple has decided to build their new home with concrete. “Cost was a factor, but really, for safety, it’s negligible. Almost nothing.” said the Warden family. The husband works for NRMCA Producer member Dolese Bros. in Oklahoma City. The shell of the home costs about 15% more than traditional construction. However, heat and air units cost about 50% less, because the home is so energy-efficient. After construction, utility bills are 40% to 60% smaller each month than bills in an average home.

Source: A November 19 posting by KFOR TV in Oklahoma City. Read more and view video clip here.