“We take architectural concrete very seriously and we partner with those vendors that can appreciate and share our goals regarding finished architectural concrete quality. I am proud to express our appreciation of Superior Materials and its’ people on this project. Thank you for making our first experience in Farmington Hills a great one.” – Team Landmark

Superior Materials can help with unique, specialty-engineered projects like the Farmington Hills Water Tower, which began construction in 2012 by Landmark Structures. Since 1985, Landmark Structures, based in Fort Worth, Texas, has constructed more than 800 elevated tanks across 35 states and Canada. Construction of the structure began in November 2012 with a continuous monolithic pour of the mat foundation, which measured 7′ thick by 95′ in diameter. Over 1,300 cubic yards of concrete were placed in under 10 hours using a concrete pump and a tele-belt, with an average production rate of 130 cubic yards per hour. Despite the ambient temperature being just above freezing, the concrete temperature was maintained above 60°F by batching with hot water.

Construction continued in the spring of 2013 with the placement of the 160′-tall by 60′-diameter pedestal structure, built using a custom-designed jumpform wall system aided by a tower crane. The cylindrical wall, over a foot thick, was completed in 22 placements over a two-month period. Strict quality control measures were enforced to ensure both concrete strength and color uniformity throughout the process.

The concrete structure was capped with a 160-cubic-yard domed slab on top of the pedestal.

Michigan Concrete Association Award – Special Innovation

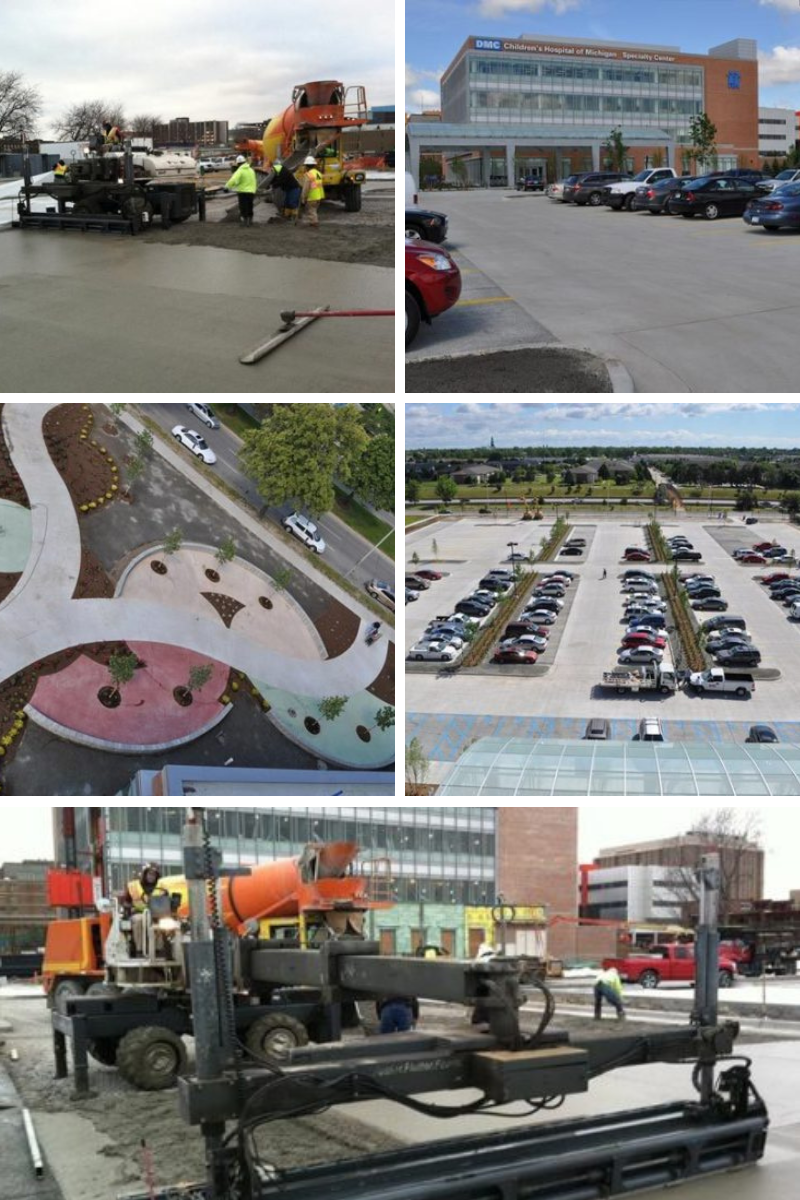

Located across the street from Children’s Hospital of Michigan, the new Pediatric Specialty Center consolidates outpatient services in a flexible facility that specializes in providing primary and preventative care for Children’s Hospital. The five-floor, 105,000-square-foot facility includes a general pediatric clinic, comprehensive outpatient rehabilitation clinic, and specialty clinics. The facility provides services such as:

The new Pediatric Specialty Center’s on-site amenities will be able to improve the overall experience, providing for a more spacious, child- and family-friendly environment.

The project architect took great care to incorporate environmentally friendly features, including low-flow faucets, high-performance water heaters, and a boiler system, as well as the use of natural light and motion sensors. Another sustainable choice for the project was the use of concrete for the center’s new large surface parking lot, which provides a bright, safe environment for visitors entering the facility. Porous exterior pavement was also incorporated into the parking lot design. This porous pavement allows rainwater to pass through the concrete and seep into the ground, reducing the load on storm sewer drains.

Albanelli placed the porous pavement in the parking stalls in 18-foot strips using a 23-foot roller screed. The conventional concrete used in the project was placed using a Somero SXP 3D Laser Screed and by hand with Weber vibrating screed boards. The integral color used for the project was L.M. Scofield Solachrome, which has a high solar reflectance index, contributing to additional LEED points for the project. The entire project is seeking LEED certification from the USGBC.

Michigan Concrete Association Award – Commercial Parking Lot

A new Wal-Mart Supercenter was constructed at the Novi Town Center in the City of Novi during 2011 and 2012. The 12.8-acre building site includes:

The Wal-Mart development team took great care to make sure the building and surrounding property was aesthetically pleasing and fit in with the entire Town Center site. The parking area, loading zones, and crosswalks were all constructed in concrete. Decorative concrete was also placed to enhance the crosswalks.

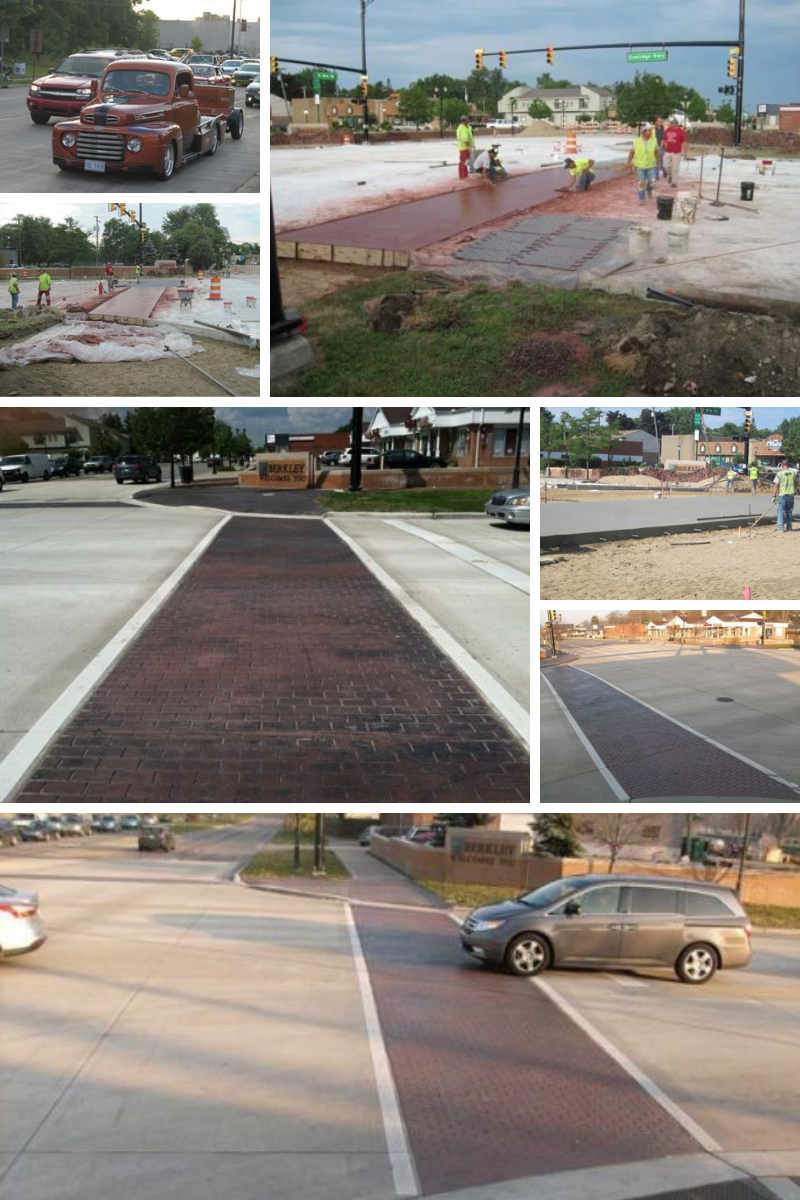

Michigan Concrete Association Award – 2012 Intersections

This very busy intersection near the center of downtown Berkley was in desperate need of repair due to the brick pavers that were not performing adequately under existing traffic loads. The major challenge for this project required the contractor to complete the work within a tight time frame during the summer of 2012. It was critical to the community to have the road opened to traffic by the weekend of the Woodward Dream Cruise, which brings many visitors to the Berkley area. Florence Cement Company met the challenge and provided a superior product.

To expedite the project, The City allowed the entire intersection to be closed to traffic during construction. The existing intersection was removed and replaced with new 10-inch plain concrete placed over 8-inches of compacted sand. ADA ramps were constructed, and decorative colored and stamped crosswalks were installed. The project took only six weeks to complete under the full intersection closure, including final restoration, clean-up, and pavement marking application. August 6, 2012 was the deadline for completion and Florence Cement successfully met all deadlines completing the project in plenty of time for the Dream Cruise event.

Michigan Concrete Association Award – Urban Arterials <30,000 yds.

The Rochester Road project was a significant project for the City of Rochester because of the impact it had on many of the businesses along this main street corridor. Angelo Iafrate Construction Company faced many challenges with this project as it was very complex from a design, staging, and traffic control perspective. Unique features on the project included the removal and replacement of the circa 1890 water main, vibration monitoring for centennial main street buildings, excavation of an Indian skeleton archeological site, abandonment of an old coal bin, and strict scheduling requirements for full closures during construction phases. The new streetscape infrastructure included a sprinkler system, decorative lighting, and conduit system underneath an exposed aggregate sidewalk. It also required major coordination and troubleshooting to fit into the existing tight area. All of this was to be achieved while the local community events occurred throughout the year.

A major key to the success of this project was the excellent coordination between Iafrate’s paving crew, the QC testing firm, and the concrete supplier, Superior Materials. On many occasions, aggregate sampling and testing for a second consecutive day’s pour would have to occur late in the evening of the night prior to the pour, in order to complete MDOT’s testing and documentation requirements. This resulted in many late nights for the testing team members.

Due to the impact of this project on the community, a major media blitz was initiated by both MDOT and the Rochester Downtown Development Authority (DDA). Weekly meetings took place to get everyone up to speed on the construction progress. This information was then conveyed via website, local media, weekly newsletters, and Facebook to the community. A store front within the project limits was also leased and the project limits, as well as historical artifacts found during construction, were visible for people to look.