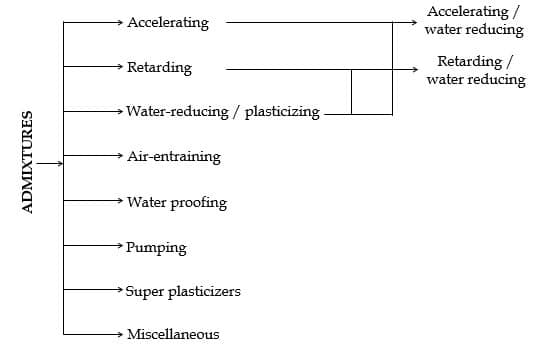

Air-Entraining Agents

Air-entraining agents are added during mixing to produce microscopic air bubbles in concrete. These bubbles increase resistance to freeze-thaw cycles, improve workability, and reduce bleeding and segregation in concrete mixtures. Air entrainment is typically specified for exterior concrete slabs and is not necessary for interior concrete.

Water-Reducing Chemicals

Water-reducing chemicals serve two main purposes:

1. To lower the water content, which increases the strength of the concrete.

2. To achieve a higher slump with the same water content, useful for pumping concrete or working in hot weather. Mid-range water reducers tend to perform more consistently across a wider range of temperatures. Retarders Retarders delay the initial set of concrete and are primarily used in hot weather conditions.

Accelerators

Accelerators shorten the initial set time of concrete and are recommended for use in cold weather or fast-track construction, where early strength gain is critical. Calcium chloride is the most common and least expensive accelerator for non-reinforced concrete. Non-chloride accelerators are specified when corrosion is a concern or when placing concrete in sub-freezing conditions.

Superplasticizers (High-Range Water Reducers)

Superplasticizers are a special class of water-reducing chemicals used to produce high-strength concrete for applications such as pumping or working with congested steel reinforcement. They are also essential for self-consolidating concrete (SCC) mixes.

United Materials

United Materials Superior Materials

Superior Materials Prairie Materials

Prairie Materials Canada Building Materials

Canada Building Materials VC Global

VC Global